Motor: How much wattage do you need? I am not sure, but approximately 100

watts for every 100 lbs you want your train to pull

is my best estimate for now.

There is not much incremental dollar cost in getting more wattage, but

battery duration will be less.

I suggest 250 watts minimum.

You can run 2 motor trucks or cars, with 2, 250 watt motors connected to the

battery and controller in parallel if they are identical motors. This may make your train more versatile

for pulling lite and heavier loads.

Calculating speed for electric motors

using # 25 chain (my original engine):

The formula to

calculate train speed is: Motor

rpm X wheel circumference (ft) X 60min/hr X mile/5280ft X motor gear /drive gear

teeth= miles per hour

24 volt, 250-500 watt Scooter electric motors for #25 chain typically spin at 2600 revolutions per minute

Wheel diameters for the engines I build are typically 6 inches, so wheel circumference = Pi X D= 18.84 inches = 1.57 feet per revolution

Scooter electric motors typically have 11 teeth, but 9 teeth also available

Drive sprockets on engines have 55 teeth (with 4.5 inch outer diameter). A 65 teeth sprocket, outer diameter 5.5 inches is also available that would fit on an axel using 6 inch diameter wheels.

From the above

equation: 2600 X 1.57 x 60 x 11 / 5,280 x 55 = 9.27 miles per hour maximum speed at

24 volts. That is very

fast for a train.

Calculating speed for the 24 volt,

350 watt gear reduced motor for regular bicycle chain (my new engine)

The 24 volt, 350 watt

gear reduced motor spins at 480 revolutions per minute. It is

a scooter motor with high rpm with internal gear reduction to slow it down

(high torque).

The formula to

calculate train speed is:

Motor rpm X wheel circumference (ft) X 60min/hr X mile/5280ft X motor gear /drive gear

teeth= miles per hour

Wheel diameters for

the engines I build are typically 6 inches, so wheel circumference = Pi X D=

18.84 inches =

1.57 feet per revolution

The gear reduced

motor has 9 teeth.

Drive axel sprockets

for bike chain that I use have from

18-24 teeth (the Thomas engine has 18 teeth)

From the above

equation: 480 X 1.57 x 60 x 9 / 5,280 x 18 = 3.54 mph max speed at 24 volts.

If you connect the motor via a switch to 24 volts, you will get full speed. If you connect the motor to 12 volts, you will get approximately ½ the maximum speed. The Thomas engine in the video is operating using a single 12 volt car battery with no speed controller, at approximately 1.75 mph (slow speed for little 2 year old grandkids but probably too slow for older kids). For example, if I want to speed it up, I could use 8 inch drive wheels, instead of 6 inch wheels, to raise the max speed at 24 volts to 5.7 mph by the formula; and approximately 2.85 mph at 12 volts. This combination of wheel and sprocket and motor rpm ratios might be perfec, t especially if used with a speed controller to fine tune the speed.

Batteries: I use 24 volt scooter motors, which run

on 2, 12 volt batteries hooked in series.

Scooter motor battery packs containing 2, 12 volt batteries can be

purchased from monsterscooter.com http://www.monsterscooterparts.com/trsc/rec-categories/batteries1/24vobapa and other vendors for about $30-50

dollars (higher prices give more amp hours of operation). Car batteries can also be used for

even higher amp hour capacity (The Thomas engine in the video uses a 12V car

battery, operating the 24 volt motor at half speed without a speed

controller).

Speed Controllers:

The proper way to achieve even and smooth speed control from zero to maximum speed is to use a speed controller. Make sure the speed controller matches the volts and wattage of the motor you choose, or be rated for higher power . Speed controllers typically use pulse width modulation to effectively reduce voltage. They actually turn the 24 volts coming from the battery on and off very rapidly. If on for 50% of the time and off for 50% of the time, the average voltage is 12 Volts. If on for 75% time and off for 25% time, then 18 volts; if on 25%, off 75%, then 6 volts. The picture below is a typical speed controller for the 250-500 watt, 24 volt motors used in my trains. It looks intimidating, but many of the connections are not needed.

The red and white wire goes to the 24 volt battery, the blue and yellow to the motor. The 3 wire connector goes to the hand throttle speed controller (red to red, black to black, and Green (or Blue) to Green (or Blue or White). Only 2 of the 4 2 wire connections need to be used: the one labeled power locks needs an on/off switch, or should be shorted closed or the motor will not operate; and one is a charger port for the battery. A 24 volt charger, and male / female connectors compatible with this controller can be purchased from monsterscooter.com The other 2 wire connectors are for brake lights, indictor lights, etc and do not have to be connected. Motor kits that match motors with speed controllers, throttles and chargers can be purchased from monsterscooter.com For example, a 24 volt 300 watt motor, speed controller and throttle kit can be purchased for approx.. $90 at this weblink

If you buy the motor separately, it can always be controlled by a “universal” speed controller, also sold by monsterscooterparts.com Make sure the wire you use connecting to the battery and motor are at least the same gauge, thickness as the wires used on the controller. These are the high current wires. I would add an on/off switch and fuse between the battery positive and battery port of the speed controller. (see below on how to calculate wattage or amperage of switches and fuses)

Simple, lower cost, easy to wire speed control without need for purchase of a controller.

If you are

afraid of wiring and electricity and circuits, and want a less expensive and

less complex engine control system, then calculate the max speed at 24 volts by

choosing the drive wheel size and gear reduction ratio that you want using the

speed formula. Remember, 24 volts

(2 batteries) will drive the drive at max speed; 12 volts or 1 battery at

approximately ½ the max speed.

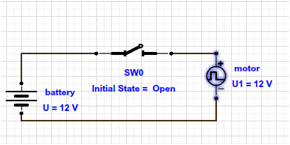

Single

on/off speed control can be achieved with a simple on/off switch as shown in

the figure 1 below. Make sure the

switch is rated for the wattage of the motor (250-500 watts). A 120 volt light switch could be

used. Switches are rated for either

watts, or amps. The power equation

is: Power (watts) = volts X current

(amps) to do the conversions, if necessary. It is a good idea to put a fuse or

circuit breaker inserted between the positive battery terminal and the left

side of sw0 to prevent burn out of the battery or motor. The switch, wire used

and circuit breaker should be rated for the correct amount of power and

amps. For example, a 250 watt 24

volt scooter motor draws a maximum of 10.4 amps. If running the motor at 12 volts steady,

it could draw up to 20.8 amps. The

fuse should be rated to blow at 21 amps.

You should not attempt to further slow the motor by connecting it to a 6

volt battery (It might draw too many amps). The monster scooter speed controllers

list the amps drawn in their specs.

Make sure to pick the appropriate fuse and on/off switch.

Figure 1

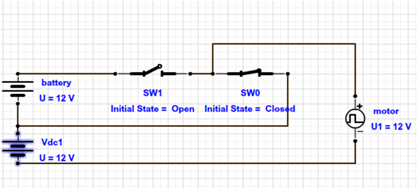

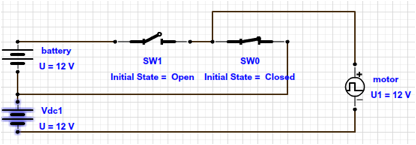

Slow, fast,

2 speed forward only speed control can be achieved by switching the engine from

12 to 24 volts with a single pull, double throw switch with center position off

as shown in the figure 2 below.

Note when sw1 is open, sw0 is closed and vise versa. This happens automatically as the 2

switch mechanisms are mechanically connected to work in this manner. Both sw1

and 0 are

opened in center position off. Again, a fuse should be placed in the

line to the motor, or between the positive terminals of each battery and the

switches.

Figure 2

Single speed with forward and reverse can be achieved using the circuit in figure 3. In this circuit, a 12 volt battery providing ½ max electric motor speed is connected to the motor using a double pull, double throw toggle switch with center position off. Note that when asking for positive 12 volts as is the case in the figure below, sub switch 3 and 1 are closed, and 2 and 0 open. When asking for negative 12 volts (which spins the motor in reverse), switch 0 and 2 would be closed, and switch 1 and 3 open. In center position off, all switches are open. Make sure the switch you use is rated for the power of the motor, and has center position off. It is a good idea to put a fuse or circuit breaker inserted between the positive battery terminal and the left side of sw0 and 2 in figure 3.

Figure 3

Low cost ($20) On/off, 50-100 foot range,

remote control

I use low

cost car remote key fob systems to switch trains on and off. The remote control relay on / off switch

replaces manual on/off switch that

is supposed to be plugged into the “ power locks” connector of the monsterscooter

speed controller to give you remote control of on/off with 50-100 foot range. Speed is selected by taping the

throttle at the desired speed. You

can power this with one of the 2, 12 volt batteries used for the speed

controller and motor, or a separate 12 volt battery. Two such low cost systems can be found at

the weblinks below: cost $16 to $20.

Please note

that the relay

switch in both products listed above is 15 amps max. If you place the switch in

the motor line, you may exceed the rated amperage as these scooter motors often

draw more than 15 amps.